Latest News

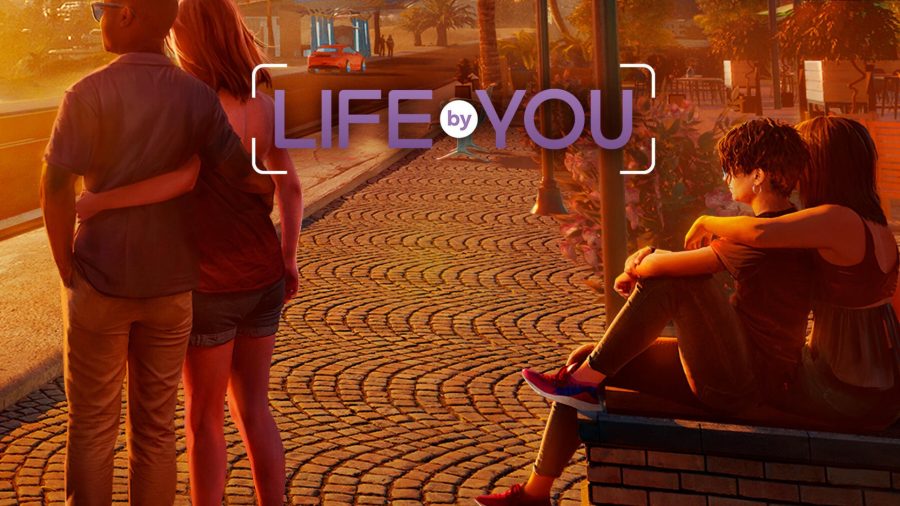

Life By You – Release date, trailers, platforms, and everything we know

Developed by Paradox Tectonic, Life By You looks to take the life sim genre even further than before with an ambitious open-world experience. This, among other features, will allow you to get fully immersed in your virtual character’s adventures, making your way around an open-world map as you go. If you’re a fan of these…