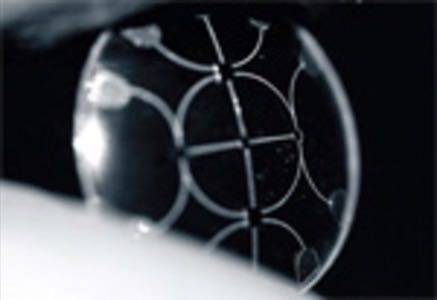

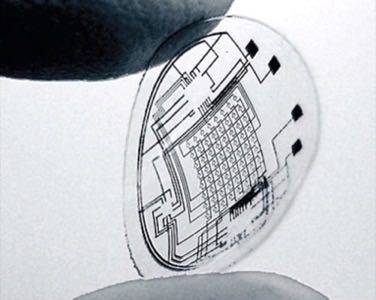

Just as many of us are getting used to augmented reality applications for cellphones and digital cameras, Babak Amir Parviz and his University of Washington students are taking it one step further. The group is working on a human machine interface where LEDs are embedded into contact lenses in order to display information to the wearer. You heard right, in a few years your cyborg eye will talk to you. In an article with the IEEE Spectrum, Parviz relays the challenges of custom-building semi-transparent circuitry into a polymer lens roughly 1.2 millimeters in diameter.

Editor’s note: This story is part of a series we call Redux, where we’ll re-publish some of our best posts of 2009. As we look back at the year – and ahead to what next year holds – we think these are the stories that deserve a second glance. It’s not just a best-of list, it’s also a collection of posts that examine the fundamental issues that continue to shape the Web. We hope you enjoy reading them again and we look forward to bringing you more Web products and trends analysis in 2010. Happy holidays from Team ReadWriteWeb!

Says Parviz, “We’re starting with a simple product, a contact lens with a single light source, and we aim to work up to more sophisticated lenses that can superimpose computer-generated high-resolution color graphics on a user’s real field of vision.”

For now, Parviz mentions that single pixel visual cues for gamers and the hearing impaired are already quite possible with the lens prototypes. The group has also experimented with non-invasive biomonitoring including checking glucose levels for diabetics.

Some of the obvious challenges of building an augmented reality contact lens include:

1. The Need for Custom Parts: Regular circuitry and LEDs are incompatible with regular contact lenses. Every piece of this project must be fabricated from scratch.

2. Physical Constraints: The group must attempt to fit transistors, radio chips, antennas, diffusion resistors, LEDs and photodetectors onto a minuscule polymer disc. Additionally, the team is required to control lens position and light intensity relative to the pupil. And finally, because the lens is so close to the corneal surface, the group must project images away from the cornea using either micro-lenses or lasers.

3. User Safety: In addition to protecting the eye against chemicals, heat and toxins, the lens components must be semi-transparent in order for the wearer to view their surroundings.

“We already see a future in which the humble contact lens becomes a real platform, like the iPhone is today, with lots of developers contributing their ideas and inventions. As far as we’re concerned, the possibilities extend as far as the eye can see.” And you thought the iPhone SDK was a tough nut to crack.

For Parviz’s complete seven-page article, check out the IEEE Spectrum’s Biomedical page.