Thinking about the future of robots and autonomy is exciting; driverless cars, lights-out factories, urban air mobility, robotic surgeons available anywhere in the world. We’ve seen the building blocks come together in warehouses, retail stores, farms, and on the roads. It is now time to build robots for humans, not to replace them.

We still have a long way to go. Why? Because building robots that intend to work fully autonomously in a physical world is hard.

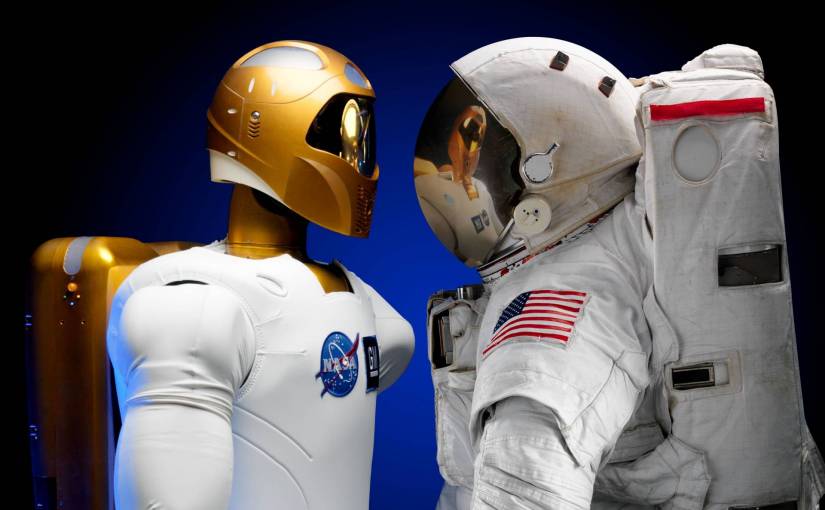

Humans are incredibly good at adapting to dynamic situations to achieve a goal. Robotic and autonomous systems are incredibly powerful at highly precise, responsive, multivariate operations. A new generation of companies is turning their attention to bringing the two together, building robots to work for humans, not replace them, and reinventing several industries in the process.

Innovation through limitation

New methods of ML, such as reinforcement learning and adversarial networks, have transformed both the speed and capability of robot systems.

These methods work extremely well when:

- Designed for well-known tasks.

- Within constrained environments and limited variable change.

- Where most end states are known.

Where the probability of unforeseen situations and ‘rules’ are low, robots can work miraculously better than any human can.

An Amazon robot-powered warehouse is an excellent illustration of well-characterized tasks (goods movement), in constrained environments (warehouse), with limited diversity (structured paths), and all end states are known (limited task variability).

Robots in a complex world

What about in a less structured environment, where there are greater complexity and variability? The probability of errors and unforeseen situations is proportional to the complexity of the process.

In the physical world, what is a robot to do when it encounters a situation it has never seen before? That question conflicts with the robots’ understanding of the expected environment and has unknown end states.

The conflicted robot is precisely the challenge companies are facing when introducing robots into the physical world.

Audi claimed they would hit level 3 autonomy by 2019 (update: they recently gave up). Waymo has driven 20 million miles yet operationally and geographically constrained.

Tesla reverted from a fully robotic factory approach back to a human-machine mix, the company stating, “Automation simply can’t deal with the complexity, inconsistencies, variation and ‘things gone wrong’ that humans can.”

Yes — this complex issue will be figured out — but the situation is not solved yet.

To solve these problems in the physical world, we’ve implemented humans as technology guardrails.

Applications such as driverless cars, last-mile delivery robots, warehouse robots, robots making pizza, cleaning floors, and more, can operate in the real world thanks to ‘humans in the loop’ monitoring their operations.

Humans are acting as either remote operators, AI data trainers, and exception managers.

Human-in-the-Loop robotics

The ‘human in the loop’ has accelerated the pace of technology and opened up capabilities we didn’t think we would see in our lifetime, as the examples mentioned earlier.

At the same time, it has bounded the use cases to which we build. When we design robotic systems around commodity skill sets, the range of tasks is limited to those just those skills.

Training and operating a driverless car, delivery robot, or warehouse robot all require the same generally held skill sets.

As a result, what robots are capable of today primarily cluster around the ability to navigate and identify people/objects.

As these companies bring their solutions to market, they quickly realize two realities:

(1) Commodity tasks make it easier for others to also attempt a similar solution (as seen with the number of AV and warehouse robot companies emerging over the past few years).

(2) High labor liquidity depresses wages, thus requiring these solutions to fully replace the human, not augment, in high volumes to generate any meaningful economics. E.g., Waymo/Uber/Zoox needs to remove the driver and operate at high volumes to turn a profit eventually.

The result of the commodity approach to robotics has forced these technology developers to completely replace the human from the loop to become viable businesses.

Changing the intersection of robotics and humans

The open question is: is this the right intersection between machine and human? Is this the best we can do to leverage the precision of a robot with the creativity of a human?

Expert-in-the-Loop robotics

To accelerate what robots are capable of doing, we need to shift focus from trying to replace humans, to building solutions that put the robot and human hand-in-hand. For robots to find their way into critical workflows of our industries, we needed them to augment experts and trained technicians.

Industries such as general aviation, construction, manufacturing, retail, farming, and healthcare could be made safer, more efficient, and more profitable. Changing the human’s role of operator and technician to manager and strategist.

Helicopter pilots could free themselves from the fatiguing balance of flight and control management. Construction machine operators could focus on strategies and exceptions rather than repetitive motions.

Manufacturing facilities could free up workers to focus on throughput, workflow, and quality, rather than tiring manual labor. Retail operators could focus on customer experiences rather than trying to keep up with stocking inventory.

These industries all suffer from limited labor pools, highly variable environments, with little technology, and high cost of errors. Pairing robotic or autonomous systems that work hand in hand with the experts could invert from the set of dynamics compared to commodity use cases.

Companies could build solutions that need only to augment the operator, not replace him or her, to meaningfully change the economics of the operation.

Building for an expert-robot generation

The current generation of technology innovation is starting, with a new generation of companies using robotics and autonomy to change the operating experience across industries.

- Innovative companies such as Skyryse* with complex aircraft flight controls.

- Built Robotics in the construction.

- Path Robotics in manufacturing.

- Caterpillar in mining.

- Blue River in agriculture.

- Saildrone in ocean exploration.

- Simbe Robotics* in retail.

- Intuitive Surgical in healthcare.

Robot solutions that share many key dimensions:

- Introduce advanced levels of automation or autonomy that can pair with its human operator.

- Deliver at least two of the three value dimensions: safer operation, improved cost of operation, high total utilization of assets.

- Shift the operators’ time to higher-value tasks; eventually to manage across multiple functions in parallel.

- Primarily software-defined across both control and perception systems.

- Easily retrofit into customers’ assets base at price points less than 20% of the cost of the underlying asset.

- Can go to market ‘as a service’ with recurring revenue and healthy margins.

Technology has empowered humankind to be capable of the impossible.

The impossible means we can make more complex decisions at orders of magnitude more precision and speed. Yet so many industries still rely on human labor and operations over human ingenuity and authority.

As the world adapts to social distancing and remote work, it’s more important than ever to leverage technology as our proverbial exoskeletons to maximize what humans are great at, and let technology do the rest.

*Venrock is an investor in Skyryse and Simbe Robotics