The Internet of Things promises that every object will eventualy be hooked up to a network. And 3D printing promises that any object we can imagine, we can build—on site and on demand. And big data promises we’ll know everything there is to know about these networked objects.

What happens when you put those innovations together? For starters, reach up to the left side of your chest and consider what lies beneath.

Your Heart, Connected

The human heart is a powerful yet delicate thing. While song and story may have every heart breaking the same way, the organ actually varies from individual to individual.

Those variations in the human body have presented which the healthcare sector has contended with since, well, forever. From fashioning splints from tree branches to working with stents that open up clogged arteries in the heart, doctors and technicians have had to work to make worldly things fit as well as possible within the body.

Very soon, however, the day will come when a patient in need of a custom medical device, such as a prosthesis or stent, can have such an object manufactured within minutes right at the healthcare facility, instead of waiting for days to get the device delivered from a factory.

3D-printed medical devices could save time and money. Yet we’re missing some of the benefit if that device just gets implanted in your body and forgotten. To be part of the Internet of Things, it must somehow be scannable, so its state can get entered into a database somewhere; and those pieces of information then need to become part of the large-scale, crunchable data sets known as Big Data.

All three of these elements are pretty much present already: real-time data-analysis software that can measure and crunch the specifications for devices in minutes as opposed to days; components that can be built with unique identifiers to ensure exact assembly; and 3D printers can churn out devices on-premise on an as-needed basis.

Ideally, we’d have a circulatory system of data not unlike the veins and arteries that connect our heart: Data about our bodies would flow into 3D printers, to create just the right device at the right time; trackers would confirm that the right device is going into our body; diagnostic systems would report on its performance and warn of failures; and analytics would tell manufacturers, doctors, regulators, and researchers how a broad range of the devices perform over time.

Healthcare is not the only sector that will benefit from the maturation of these technologies: Indeed, any business with a supply chain, no matter what’s getting made and transported, could be up-ended by this confluence.

Making The Connection

It’s easy to understand the connection between Big Data and the Internet of Things: Anything connected to a network spews data, and something must collect and analyze that data.

The connection between 3D printing isn’t as clear—until you realize that 3D-printed objects, which are the physical instantiation of a design expressed in data, were born to be networked objects.

This doesn’t mean they must have a persistent Internet connection like a smartphone or tablet—but at the very least, they must have some way of signaling what they are.

See also: How The Internet Of Things Will Think

That means they need a unique identifier. You would not want your toaster, for instance, to pull in a stray command from the neighbor’s house next door and start burning your bagels. Or, more tragically, for a medical appliance you just made to go into the wrong patient. This last may seem unlikely, but doctors are trained to be scrupulously careful about their procedures, right down to using a pen to mark where on a patient’s body they will operate.

Identifying objects can be done in one of two ways: using software or firmware embedded into the device. or using physical encoding.

The first method is very similar to how our computers and other Internet-enabled devices in the home use MAC, or media access control, addresses—unique identifiers that differentiate one device from another. But MAC addresses—just a string of bits, really— and similar software and firmware approaches can be altered so one device can masquerade as another.

Physical encoding, like RFID tags or QR codes and barcodes placed on the object, is notionally more secure. But visual codes are an overlay on the object that can be removed, for one, and for two have to be oriented towards the sensing device in order to be read.

RFID tags are better since they are usually embedded within the object and thus won’t be peeled off or forced to be scanned in a certain way. But RFID tags can be jammed, inadvertently or otherwise, just like any other device that uses electromagnetic energy. And, since they are separate components, they have to be inserted in the device at some point in the manufacturing process.

For 3D printing, interrupting the printing process to stick in an RFID tag is doable, but inefficient.

Seeing Inside Things

Researchers at Carnegie Mellon and Microsoft Research may have a solution that will bring 3D printing and the Internet of Things together without the limitations of RFID or visual encoding. Using 3D printing, researchers can build unique three-dimensional codes right inside the material of the object.

Once embedded within the device, the 3D tag, known as an InfraStruct, can then be read with the use of a terahertz scanner, a device that uses the part of the electromagnetic spectrum that lies between infrared and microwave light. Terahertz scanning is already used right now in medical imaging devices.

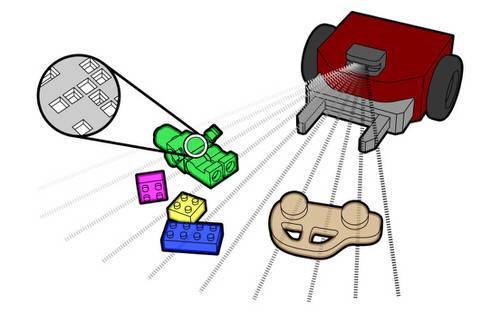

The ability to directly embed readable codes directly within objects would mean that any object created in such a fashion could immediately be a part of the Internet of Things. The example used by Carnegie Mellon’s Karl D.D. Willis for the InfraStruct project was a robot equipped with a terahertz scanner that could seek out and find an encoded object. That might be a vacuum cleaner trying to avoid some toys on the floor, or a factory robot seeking the exact part it needs to deliver to the assembly line. For all kinds of robotics applications, that kind of functionality would be phenomenal.

In the past, terahertz radiation, which can see though most non-metal objects without damaging living tissue (as microwaves do), was expensive to generate. But recently, scientists at the University of Texas Dallas announced breakthroughs in developing a microchip that could be used as a terahertz scanner, even inside a smartphone. Given that smartphones will likely be our personal connection and control device to the Internet of Things someday, that would bring the Internet of Things much closer to everyday objects in our lives.

Willis also sees potential uses for this technique in real-time game interaction, with manufactured objects being put into play, literally.

Taking Heart In The Internet Of Things

Going back to the example of our frail, human heart: This kind of scanning technology could even be used for the printed-on-demand medical devices. Specialized stress markers could be built into the device using a modified InfraStruct technique, just as an ID maker can be embedded. If an implanted 3D-printed device were to become damaged or fatigued, its built-in markers would become distorted—something easily picked up by a regular terahertz scan.

That fact, in turn, could then speed through the Internet of Things, where Big Data algorithms would spot the anomaly, print a replacement, and schedule an operation to insert the new item.

These scenarios are closer than we think to reality. Once we link together innovations like 3D printing, the Internet of Things, and Big Data, the sky’s the limit on what we can dream up. We won’t just be able to build any object we need—it will instantly become part of our networked world.