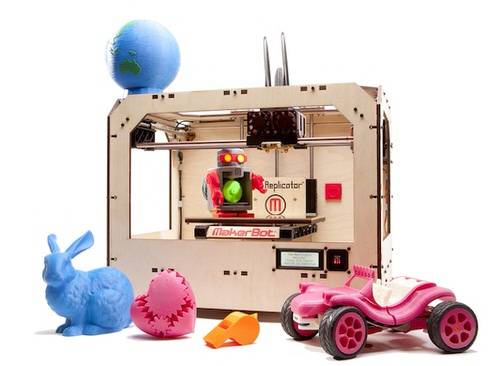

MakerBot is a company that manufactures 3D printers. A “3D printer” sounds like something boring, so MakerBot Industries has chosen an excellent name. A 3D printer is a device that creates physical objects from digital plans. You can fill it with ABS (what Lego blocks are made of) or PLA (biodegradable and made of corn), download or make designs on a computer, press “go,” and create replicable, real objects.

Now it’s sounding pretty cool, right? Today, MakerBot announced the Replicator, its newest model, which will be unveiled at CES tomorrow. Starting at $1749, you can print objects the size of a loaf of bread from a device that can sit on your desk. If you pony up a little more, you can get the Dualstrusion model, which lets you print two-color Earths or hearts. Not sold yet? How about in 10 years, when you never need to wash (or even buy) dishes again?

Today’s MakerBot is positioned for “personalized manufacturing,” but it’s mostly for practice. You can only make whatever you’re able to make out of Lego-like materials. That’s still amazingly powerful, though. Earlier this year, MakerBot got its own artist in residence. But MakerBot’s marketing talks mostly about what it will do in the future.

“[P]arents and educators with a MakerBot Replicator offer the next generation an opportunity to learn the digital designing skills required to solve the problems of the future,” today’s blog post says. “Students with access to a MakerBot have an edge in the future job market. Just like the youth of the 1980’s, who had access to computers, children with access to a MakerBot Replicator will become the leaders who make a better tomorrow.”

So what will it do tomorrow? Here’s the example I always use when I talk about the potential of 3D printing. Imagine never having to wash the dishes again. While you’re getting dinner ready, just pick the plates, cups and cutlery you need on your computer, hit “print,” and they’ll be ready by the time you set the table. After dinner, you don’t need to wash them. You don’t even need to rinse them. Just drop them in the tank of your 3D printer, which will melt them down and get the material ready for reuse.

That one isn’t even farfetched, since it would only require the same kinds of materials MakerBots already use. Think about 3D printing of organic materials: Heart valves? Whole organs? What about food? Imagine nanoscale 3D printing that can assemble things atoms at a time! At that point, the possibilities become almost limitless.

If(/when) 3D printing becomes commonplace, imagine the market on the Web for designs. Not only would it be a new economy for people with 3D design skills, it would have profound effects on retail. Instead of buying preexisting objects, we could simply download the plans and print them out.

If you’re still having trouble imagining the world 3D printing could (literally) create, crazy sci-fi man Cory Doctorow has written a book about it. It’s called Makers, and the digital versions are free, DRM-less, and available in all kinds of formats (you’ll see on the download page). It’s about a near-future with some of the trouble towards which our present world seems headed, but the ability to print custom tools is the one cutting edge regular people still have.

With MakerBot pushing things forward in 3D printing, we already live in a world where the Web allows us to transmit physical objects. If you’re interested in a high-tech future, 3D printing is a trend to watch closely.