3D printing seems to be everywhere these days, used to create everything from handguns to headphones. But what does it really take to get started: How much does it cost, how difficult is it to use, and how do you actually get your hands on a 3D printer?

Last week, a law student from the University of Texas in Austin leased a printer made by Stratasys, the uPrint SE 3D. He wanted it to create a prototype of a 3D-printable handgun. Turns out Stratasys didn’t much like that idea, so it took back the printer, saying the student’s lack of a firearms manufacturer’s license made what he wanted to do illegal. (For more on this topic, see John Paul Titlow’s story on How 3D Printing Is Inflaming The Gun Control Debate.)

A Reuters story , meanwhile, found that the European Union is asking member countries to invest in 3D printing technology to speed up and raise manufacturing output.

So just how hard is it for an average person get access to one and actually start making things?

Why would you want a 3D printer, anyway? Because you can make just about anything with one. From utensils to iPhone cases and apparently weaponry, 3D printers can create just about anything your imagination (and a quality computer-aided drafting and design – CADD – software) can create. It’s like an Easy Bake Oven for computer geeks.

How Much Do 3D Printers Cost?

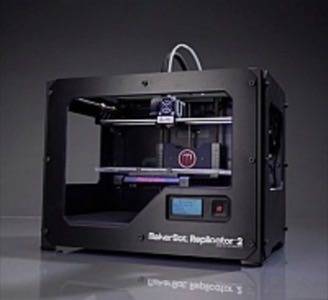

Until fairly recently, 3D printers were available only to major industries to create prototypes or cheap and functional products. Now, anyone can get do-it-yourself 3D printing kits from sites like MakerBot for about $1,500.

If you want a more sophisticated machine, though, you’ll probably have to deal with a sales rep. That’s how Stratasys, the company currently embattled with the law student, sell its machines. The company offers leasing programs for its printers that range from $185/month to $299/month. If you wanted to buy one flat out with no leasing, you’d have to pony up about $10,000. Just this year, CNET reviewed three different types of consumer-available 3D printers that you can log on and buy, no sales rep needed, with prices ranging from $500 to $2,000.

If you don’t have a printer of your own, you can still get 3D models printed out through a service, kind of like a 3D version of FedEx Kinkos. Shapeways, a startup in New York, offers this service: just upload your model idea to the site, choose your materials, and Shapeways will give you a pricing estimate. Within a few weeks, the company will print it out and ship it to you. For particularly creative users who are good with software, the company offers product ideas that you can custom design and build.

How Do They Work?

The process these printers create models is fairly simple. Using a design from a CADD program, they turn 3D images into a series of thin, horizontal, virtual layers until a virtual version of what is to eventually be printed is modeled on screen. These CADD designs can be found online, or created by scanning a physical object. Designing complex objects from scratch requires a certain amount of skill and training.

Depending on the machine and the project, different materials can be used to construct the model. For the cheaper machines, plastic or resin is commonly used, while more industrial projects can employ powered metals, alloys or polycarbonate materials. There are even food-grade printers that use chocolate and sugar to create edible models.

Layer by layer, the machine lays the image out on to a heated platform. 3D systems at home printer Cube includes a platform glue that keeps the base of the project steady during printer and washes off with water. Once it’s printed and cooled, you’ll have a tactile version of something that used to just occupy space in your head.

If you are itching to print something, but are not particularly creative, a site from Makerbot, Thingiverse can offer up a few ideas. The open-source community has instructions on how to print your own products (like these functional headphones that made tech bloggers drool a few days ago) and provides an overall glimpse into the world of 3D printing and creativity.