One of the most compelling aspects of industrial IoT is the ability of sensor technology to solve problems that have plagued traditional industries for years if not decades. One such problem is machine maintenance and repairs. Up until recently, such maintenance was typically time-consuming, costly and limited by the challenge of finding appropriately skilled workers.

A start-up that is successfully responding to these challenges through a combination of IoT and machine learning is Israeli company, 3DSignals.

I spoke to Amnon Shenfeld, co-founder, and CEO to learn more. I’m always curious to learn how people get the idea for their start-up. For Shenfeld, it started with a simple train journey:

“I was riding a train in England between Cambridge and London, when suddenly the train made this terrible noise. I was trying to figure out if this was the end… but then a few seconds later if it was gone and everything was back to normal. My first thought was, I wonder if the train engineer was sitting here in this carriage, would he be able to say if the noise was normal or not and if it was a problem with the bearings, a problem with the suspension, maybe something on the tracks that the train hit, or if this is just one of the dynamic sounds that the train makes? These trains are pretty long, so I guess it’s very difficult to analyze all the different noises they make in the repair/maintenance garage. So I wondered if they let train engineers drive the trains in the garage to monitor how they sound, as this is a very clear way to understand what is going on.”

Shenfeld has a background in deep learning and he explained, “I was pretty sure I could train a neural network to recognize these sounds in order to report them automatically and classify them, then (and with some verifications by experts), build a system based on sounds that would add a lot of significant information regarding the condition of machines.”

With an idea that just wouldn’t quit, Shenfeld initiated a field trip, with a bunch of friends from various disciplines: machine learning, mathematics, electrical engineering, to a local steel plant.

“We asked the staff, what fails here often? One of the answers was saw blades, they were cutting through steel profiles and beams, and as a result, they would frequently have breakdowns. They told us something pretty amazing: ‘we have 50% efficiency and we’re very proud of it because in the steel industry it is considered a lot,'” he said.

He added that now “we’re software people, and we were shocked because if you invest all this money in electricity, manpower, equipment, physical space, you would probably want to get more than 50% uptime. They said before they took over the business they were doing 20%, and one of their main pain points was blade failures that they couldn’t predict; they would spend at least 20 minutes on each blade replacement and they would have on average 3 per day per production line.

“So we’re talking about more than an hour a day per machine spent replacing saw blades, not to mention any residual impacts on the machines if the blades shatters. They tried existing monitoring technologies (e.g. current, temperature) to no avail,” he said.

Shenfeld thought he and his friends could help and the impetus to create 3DSignals was raring to go.

Disrupting the preventive maintenance cycle

Machine maintenance is traditionally a laborious process that requires sending a physical person around each factory/plant/workplace to inspect individual machines, typically on a set schedule. It traditionally relies on an engineer to identify anomalies, and respond accordingly.

As Shenfeld explained, “People used to rely on acoustics a lot, for example in their cars, (to see if it sounded) normal or was sounding a bit strange. In the same way, a technician that can hear a pump can tell you which one is working well or not.”

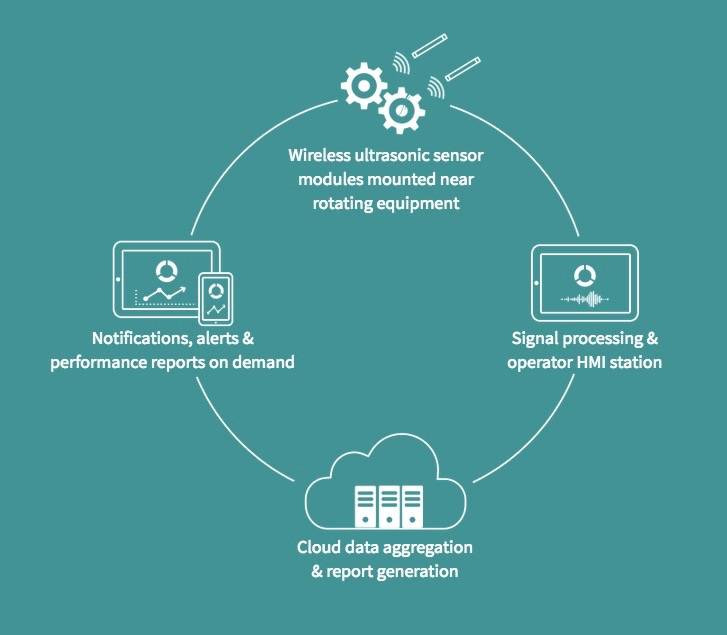

Indeed, 3DSignals is the first IoT company to utilize sensor tech to monitor machines through sound. Their system can extend to a range of machines “based on the knowledge of how similar machines are supposed to sound and also learning the very specific sound acoustics of specific machines.

This is very similar to the human process, if you were to talk to a maintenance engineer that monitors a group of machines, he knows what is normal or not for each machine and this system emulates this behavior with a neural network, in other words, deep learning.”

This all leads to increased efficiency in maintenance and the ability to predict problems so that an engineer can respond as needed rather than only within a pre-existing preventive maintenance time frame.

3DSignals system is accompanied by an easy to use platform and cloud which means that “The sound samples can even be sent to the manufacturer of the motor, pump, valve, giving them back this very natural knowledge.” It has a natural affinity with the energy industry, he said, where “they’re having so many turbines spinning with no people next to them…They come for their routine maintenance to fix a pump, then notice an entirely different piece of equipment is failing due to how it sounds. They didn’t have any other method before us.”

Sound tech has largely been researched in academia for voice recognition, particularly in deep learning and algorithms. As Shenfeld notes, “We’re on the cutting edge of developing software and algorithms and developing automated hearing. It’s very exciting.”

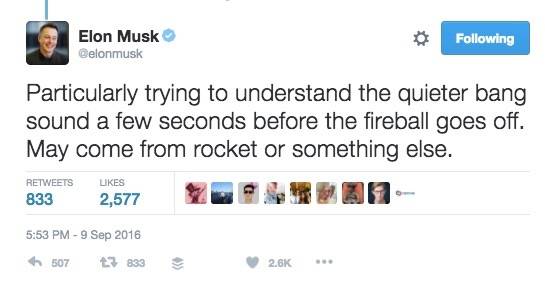

Even Elon Musk relied on a mystery sound to try and solve the Space X Falcon 9 explosion:

Shenfeld explains that in presenting his idea to companies he asked rooms full of suited staff “Would you know how your machine is working by the sound? I never get a no.” With a technology that has a natural affinity with a range of sectors from mining to agriculture to automated cars, this won’t be the first time you hear about 3DSignals.