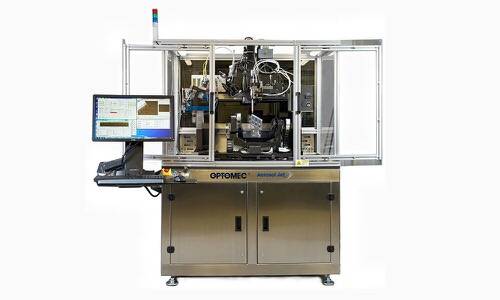

In less than a month, Optomec’s Aerosol Jet 5X printing system has become a hit with companies looking for a 3D printer to build smart products for their Internet of Things (IoT) systems. The New Mexico-based company revealed a large uptake in orders from industry leaders in defense, healthcare, aerospace, and automotive, including GE Healthcare Systems.

According to 3DPrint, companies in these industries are lining up to purchase the new Aerosol Jet 5X printing system, already seeing the immense capabilities of the new printer.

See Also: 10 Crazy Things 3D Printers Can Make Today

While Optomec did not reveal the names of any other “industry leaders” or give us sales numbers, GE Healthcare Systems AME senior electrical process engineer Steve Crynock gave a positive impression of the 3D printer.

“With the Aerosol Jet 5X system we expect to iterate quickly to provide optimized 3D-printed electronic solutions enabling engineers to create smaller, lighter, and more efficient products,” Crynock says.

Optomec new system can print down to 10 microns

The Aerosol Jet 5X printing system offers a five-axis coordinated motion platform that can print as small as 10 microns, making it ideal for small circuitry and cable. Previous 3D printers have been unable to print circuitry at such a small size, which made them rather inefficient when compared to traditional tools and machinery.

According to Optomec’s website, the 3D printer also supports a wide variety of materials, including polymers, adhesives, inks, and dielectrics. The 3D printer features a patented additive and aerodynamic material deposition capabilities and Optomec claims the printer can meet the demand of a busy factory floor.

“We are pleased to see the rapid adoption of our recently introduced Aerosol Jet 5X system by multiple companies across a variety of industries,” said Mike O’Reilly, director of Aerosol Jet’s product management. “This solution is enabling next generation 3D electronics in ways not possible with current manufacturing methods.”